The biggest challenge facing businesses is innovation. For years, we have seen a high rate of digitisation in Italy. So let’s see how the economic ecosystem is changing…

Which sectors are being affected by digitisation?

Digitisation has taken root across the company. The applications deriving from computer algorithms are used in an undifferentiated way both in administration and in finance or in the marketing area. What is really surprising, however, is how all sectors and micro product sectors have been “overwhelmed” by the long wave of digitization. For example, here are some examples:

- Robotics

- Sensors

- Big date

- 3d printing

- Logistics

- Software applications

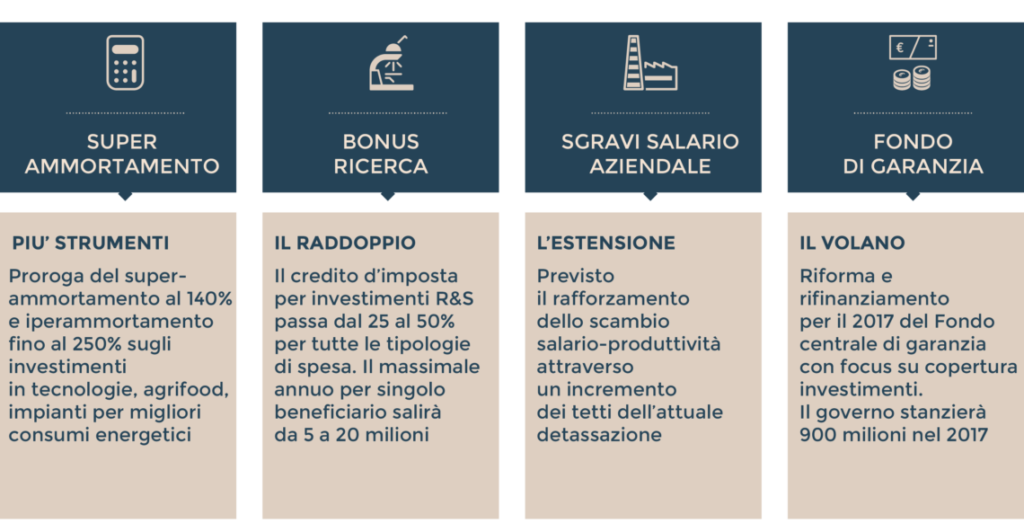

“Piano Industria 4.0” made a significant contribution to this digital transformation. This multi-year industrial development plan offers concrete financial support to all companies through a series of measures designed to capture the effects of the fourth digital age, i.e. the optimisation of costs in relation to the resources used.

Below is a sheet published by the Ministry of Labour and Economic Development summarising the targets for the three-year period 2017 – 2020.

Internet of Things: networked products enriched with artificial intelligence

The transformations described here have led to the conception of the so-called “smart factory”. A distant relative of the Ford assembly line, the modern factory is highly automated in its processes, but it is connected to the network through artificial intelligence, i.e. artificial intelligence predictive algorithms. Artificial intelligence represents that particular algorithm that is able to analyze a huge amount of data and make decisions as a result. For example, if we think about FCA’s assembly line, it is plausible to think that each production line is attenuated by software that returns a complete picture in real time on an electronic device through insights to be interpreted. Again, in the case of the mineral water storage centres, where historically the main problem lies in the management of the warehouse, it will be the task of the automatic robots to transport from one side to the other the piles of water pallets to facilitate their exit from the storage centre. Finally, in the famous case of the black box that we have installed on our cars, we observe how the connection to the Network returns to the screens of the Service Provider the situation in real time that occurred before the crash, immediately activating the first contact with the driver.

These examples allow us to introduce the concept of “Internet of things” to define the existence of new objects connected to the network that provide new data, which, in the case of the smart factory, are interpreted by the employee in order to make the relevant decisions.

Do you want to be always updated? Keep following our blog and follow us on our Facebook and Youtube page.