According to the World Health Organization (WHO), health is the science and technology of preventing disease, increasing life expectancy, educating personal health to people, providing medical services for immediate diagnosis and treatments, and developing and completing social services to meet the needs. Safety is one the most important aspects of health in health service system [1]. One of the most important issues in the health section is the quality of care. The quality of care consists of group of elements, that patient safety is one of the most important parts of them [2]. Patient safety plays a vital role in health care [3]. In health organizations all around the world, patient safety is one of the main concerns of service providers. These days’ patient safety is a key concept in the health system and it is known as one of the important indicators of service quality control [4]. Despite of this, studies show that nowadays, clinical errors are one the most important issues in health care providers` environment that threatens patient safety [5]. Despite the fact that errors are one of the factors that threaten the safety of patients and many efforts are to reduce errors in clinical environments, errors still occur in clinical environments [6]. In developed countries, approximately one in ten patients are injured while receiving hospital care that half of them are preventable [7,8]. It is also estimated that 134 million adverse events occur in hospital in developing countries each year, resulting in

2.6 million deaths due to unsafe care [9]. In fact, all members of medical team, regardless of how skilled accurate and committed they are may make mistakes during clinical care [10]. In a study, Armstrong and his colleagues stated that by increasing the quality of nurses` work environment, the culture of patient safety can be increased [11]. Nurses are important member of the care team and as the biggest human resource of health care organizations, they play a significant role in advancing goals [12,13]. Psychologists believe that mistakes in human actions are inevitable and are a part of human reality According to studies 38% of medical errors are related to nurses [14]. Tiller G [15] defines nursing errors as shortfall in performing care standards and consider the basis of these standards to professional duties and responsibilities. Nursing error is an unintentional error [16,17]. Drug administration is one of the most important and complex processes of nursing care [18]. Approximately 40% of nurses` time in each work shift is spent on drug therapy [19]. Among clinical errors, medication errors are one of the most common clinical errors [20,21]. In the definition of medication errors, it is stated that it includes that include errors in prescribing the amount of medication, mistakes in prescribing and ordering, not prescribing the correct medication or medication formula, using expired medications, mistakes in the time of medication administration, and lack of awareness about the side effects caused by the combination of some special drug [22]. Researches show that 7000 of the 44000 to 98000 annual deaths caused by medical errors are caused by medication errors. The annual costs of deaths and side effects caused by drugs in United States is estimated between 1.65 and 5 billion dollars. Most of the costs are related to hospitalization due to inappropriate use of drugs or not receiving the right drug, giving inappropriate drugs and unwanted side effects [23]. In addition to this, studies of European countries show that 19 to 28% of hospitalized patients experience medication errors. In studies Seki Y and Yamazaki Y [24] in Japan, the highest amount is related to the lack of appropriate time of the drug. In Jordan 48% of medication errors were related to nurses, that 26% of the wrong doses were reported and in the studies of Mirzaei M, et al. [10] the prevalence of medication errors among the nurses was reported to be 79%. Furthermore, one of the most common groups which medication errors occur is nursing students [25]. In a study by Cebeci F, et al. [26] in Turkey, it was found that 38.3% of nursing students had medication errors. In another study, 48.5% of nursing students had at least one medication errors. Medication errors J Bioengineer & Biomedical Sci, Volume 13:4, 2023 for various reasons, such as lack of knowledge, increased workload, and failure to follow instructions. These errors may occur at different stages of the drug treatment process, such as when ordering, preparing, distributing and prescribing drugs. However, most errors occur in the administration phase [27-29]. Currently, according to the topic and results of the research, one of the most important medical errors is medication error, which cause irreparable side effects and causes a lot of damage to the treatment system. The purpose of this research is to design and create a device to prevent medication errors. This idea has been registered in the Patent Organization of Iran under invention number 99484.

Materials and Methods

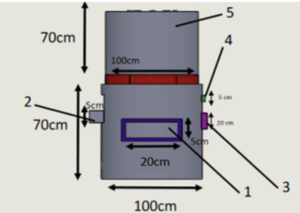

This project started with a new researcher idea then by searching in the scientific content of articles and book, the title and proposal the project was compiled with opinion of the supervisor. Then model of the device was designed in collaboration with graphic & mechanical engineers Finance. The main tool was invented by the researcher. By mechanic engineer and solid work, the design of this tool with professional software with academic-theorical proposal researchers Mahmoudi M, et al. [30] about it is designed for the prevention of medication errors and the correct implementation of drug therapy. This idea is designed by soft wares and then the file of this designing was transferred to laboratory by researcher and work mechanic engineer in order to hardware designing and mockup. The structure of orthosis was discussed in terms of all angle’s morphology, measurement of figure based on standards and again after changing s figures and measurement was redesigned by software expert. The medication error prevention device (height: 160 cm, width: 100 cm, depth: 100 cm) is composed of: (a screen: of length: 20 cm, width: 5 cm, a barcode reader: length of 20 cm, a place for medicine containers: length: 8 cm, width: 5 cm, medicine outlet: length: 8 cm, width: 5cm, air conditioning compartment: length: 10 cm width: 7 cm, on/off switch: length: 5 cm, medicine compartment: length: 70 cm width: 100 cm, drug location: length: R=100 cm, sensor location: R=100 cm, mechanical lock: length: 3 cm, width: 2 cm, flashing light: R: 0/5 cm, memory: length: 2 cm width: 2 cm). According to the hospital environment, the body of the medicine checker is made of aluminum, which can be used in medical industries and has the ability to be sterilized. The way it works is as follows: First, the drugs are located in the drug store (Figure 1 – Number 5), by connecting the drug checker with the ability to prevent drug errors to the hospital system (electronic health file), the information of the patients’ files is transferred to the memory (Figure 3- Number 10). (The connection is within the network and also via Wi-Fi). When the desired drug is determined based on the processing of patients’ files by the memory, the drug is released from its position (the drugs are arranged in a row) after being released, it is transferred to the location of the drugs (Figure 3 – Number 12). The sensors are located in the lower part of the drugs’ location (Figure 3 – Number 12) and (Figure 3 – Number 11). Each of the sensors, in turn, checks the name of the drug, the expiration date of the drug, and the dose of the

drug according to the labels and barcodes inserted on the drug and is matched with the drugs registered in the file. After checking the drugs by the sensors, the drugs are released from the desired locations (Figure 6 – Numbers 1-6) and after passing through the areas (Figure 5 – Number 4-6) They will be moved to the drug exit location (Figure 2- Number 6) and the person in charge will put each patient’s medication in the drug container which is located (Figure 1- Number 2). According to the drug information bank that is in the memory, each patient’s file has been examined during the drug preparation process in terms of drug interactions, how to take the drug, how to inject the drug, the amount of dilution of the drug, the necessary training for the patient and It shows the points on the display screen (Figure 1- Number 1). The person responsible for drug therapy is identified by registering the fingerprint embedded on the screen (Figure 1- Number 1), and the actions in his name are recorded in the registration system and consumable items are also included in the patients’ files, which has reduced the workload of the treatment system and provides more time for the treatment staff to take care of the patients. At the end of each working shift, the built-in memory (Figure 3- Number 10), reports the amount of consumed and remaining items so that the shortages could be eliminated. To compensate for the lack of medicine and to place the medicine correctly in its place, the person in charge first places the medicine in front of the barcode reader (Figure 1- Number 3), then the location of the medication will be displayed by a flashing light (Figure 4 – Number 9) and due to the mechanical lock (Figure 4 – Number 8), the lock of the other parts is closed and the lock of desired area is opened so the drug placed in its correct place, so that the problem of the correct placement of the medicines, which is one of today’s challenges in hospital wards will be solved By installing the air conditioning chamber (Figure 4 – Number 7), the appropriate temperature is provided for the medicines to prevent them from spoiling. After connecting the drug checker to the hospital system (the connection is within the network and also through Wi-Fi), the information is transferred to the memory (Figure 3 – Number 10).

For example, the patient’s file has a drug called acetaminophen, which is released according to the position of the drugs in the drug compartment (Figure 1 – number 5). After being released, it is transferred to the location of the drugs (Figure 3 – Number 12). In the lower part of the drug placement position (Figure 3 – Number 12), sensors are located (Figure 3 – Number 11). Each of the sensors, in turn, checks the name of the drug, the expiration date of the drug, and the dose of the drug according to the labels and barcodes inserted on the drug and is matched with Medicines registered in the file by memory. After checking the drugs by the sensors (Figure 3 – Number 11), the drugs are released from the desired locations (Figure 5 – Number 1-6) and after passing through the areas (Figure 5 – Numbers, 4-6) are transferred to the drug exit location (Figure 2- Number -6). (Figure 1- Number 1), after that, the medicines are available to the person in charge, and he puts each patient’s medicine in the drug container located (Figure 1- Number 2). During the preparation of the drugs for each case, the memory of each case is checked in terms of drugs according to the drug database given to the memory (Figure 3 – Number 10) and displays special points on the screen. At the end of each work shift, the amount of consumed and remaining items are checked by the memory and shown on the screen according to the number of drugs available at the beginning of the shift and the number of drugs consumed until the end of the shift. To charge the drugs, first, the person checks the drug by the barcode reader (Figure 1- Number 3) According to the location of the drugs given to the memory and according to the connection between the barcode reader (Figure 1- Number 3) and the memory (Figure 3 – Number 10) and the mechanical lock (Figure 4 – Number 8). The desired location is opened and others are locked and in this way, drugs are placed in turn, which avoids the movement of drugs in the positions. Also, with the location of the air conditioning chamber (Figure 4 – Number 7), the air temperature of the drug checker is controlled and the necessary temperature is provided to prevent the drugs from spoiling.

Discussion

This research has been conducted in the field of medicine and biomedical engineering. Considering the statistics of medication errors and its complications during providing medical care, using preventive equipment at all levels of health is felt to prevent treatment problems. According to the creative design of this plan, it is designed to prevent medication errors and errors in how the drugs are used and drugs from spoiling. The advantages of this plan include preventing nominal and formal similarities of drugs, preventing drugs from spoiling, saving nurses’ time, showing the place of medicines, checking the expiration date of registered drugs, better access to drugs, determining the amount of items consumed in the

wards, proper insertion of the drug in its place, creating a suitable temperature for medicines and preventing drug interactions.

Also, according to the research of Tolley CL, et al. [31] a study entitled The impact of a novel medication scanner on administration errors in the hospital setting before and after feasibility study and Jessurun JG, et al. [32] with title effect of automated unit dose dispensing with barcode scanning on medication administration errors: An uncontrolled before-and-after study and this research, the use of preventive equipment to prevent medication errors and their complications, as well as to prevent disability and death of patients is suggested.

Results

Based on the results of this study and other studies, one of the best ways to prevent medication errors and its complications that cause mortality and disability is using preventive devices that the preventive device for medication errors has been designed with this aim. We are ready to work with all institutions and individuals in the fields of economics, education, research and health and start-ups for this idea [33,34].

Conclusion

Medication errors are one of the main causes of mortality and disability in patients, which has considerable statistics and cause secondary problems. One of the ways to prevent this problem is personnel training and two-step checks as well as using devices and applications based on research to prevent diseases is effective. In this article, a prototype is designed to prevent medication errors. Based on the needs of the health system to prevention by constructing this device and supplying it to the market, it can be presented as a better solution than the available ways to prevent these errors.

Author: Mahmoudi, Mohammadmasoud, Fardin Rastegar, Parnia Toudehfallah and Pouyan Ghorbani

et al. “Inventing a Device to Prevent Medication Errors.” J Bioengineer & Biomedical Sci 13 (2023): 367