Machines and software of the last generation, few clicks and in a few days, if not hours, we can have before our eyes the house of our dreams.

A miracle? Yes, maybe until a few years ago. But now, with the tight advancement of new 3D printer technologies This could be widely achievable. And at bargain costs.

In the US and Saudi Arabia these technologies are already ahead and in production, so much so that in the Middle Eastern country, the houses Built In 3d printer are already in the order of the thousands. Italy also seems to have transposed the potential of these technologies, aiming at the total revolution of the building sector.

In Milan, during the Salone del Mobile 2018

, was realized the first experiment of printing construction with the creation of The Project 3d Housing 05

, by the architects Cls

together with a consortium of companies composed of Italcementi, Arup and cybe. A building of well 100 square meters -so not really a hole-equipped with living area, sleeping area, kitchen and bathroom perfectly efficient. All pulled up and prepared in a week.

A taste of the potentialities, since the architects of the Cls architect, led by the co-founder Massimiliano Locatelli, of lodgings have built at least 500 only in Saudi Arabia.

Interesting is also know how. The printer uses a compound of cement powders used in conjunction with plasticizers and other inert materials. This compound is then poured into the machine from above and directed by the central computer, which in turn gives the necessary indications to the robotic arm, the heart of the printer, certainly more versatile and dynamic than other types of more static 3D printers.

In addition, a new material is being pursued in the sector: the “Lavacrete”. A material similar to mortar but much more ductile, suitable for such constructions but at the same time perfectly according to the companies.

A “Made in Italy” Hi-tech in short, but has a strong competitor in the States. From Austin, Texas, comes the

Icon

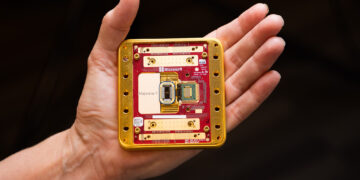

in fact, that in terms of timing has exceeded the Italian company thanks to construction projects that see a house set up in 24 hours at the negligible figure of 4 thousand euros. A record, made possible, according to the developers, by the 3D Vulcan printer.

Not really a printer like those of our homes, since this jewel of high technology USES measure 7 meters by 10 and weighs a ton. Important measures for equally important performances: It is capable of printing as much as 10 centimeters of dwelling per second.

Be clear though. It is not a technology born only to the rich. Indeed. One of the objectives is precisely that of emergency intervention in the event of catastrophic natural disasters. An example is that of El Salvador where the housing emergency is at the historical highs. And it’s no coincidence that the Icon, along with the nonprofit New Story, started last year a project that will bring to the island Salvadoran well 100 homes built totally made by 3d printing. And we’re just starting out.