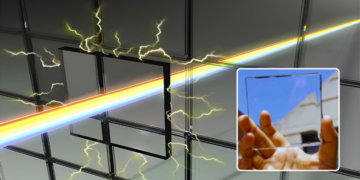

The new material is elastic, emits intense light, repairs itself when cut or drilled and reduces energy consumption and plastic waste production

Research on new materials is always evolving. Properties such as self-repair, fluorescence or conductivity in plastics would find an immediate application in several advanced fields. One of the most desired but difficult to achieve characteristics is flexibility combined with the possibility of emitting light. The direct application is the use of flexible electronic display material, one of the next expected innovations in the electronics market.

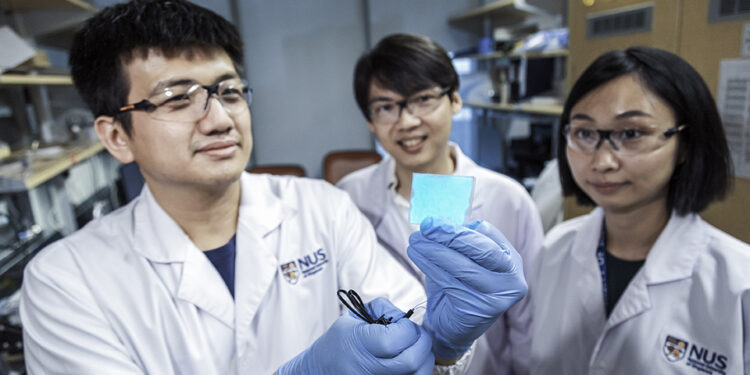

New research by the National University of Singapore presented HELIOS, an innovative material that emits light and repairs itself. HELIOS stands for Healable, Low-field Illuminating Optoelectronic Stretchable, the complete results were published in the journal Nature Materials. The material is a transparent elastic plastic consisting of a fluorescent component and a surfactant. The combination allows for high electrical permittivity and higher electrical charge accumulation at low voltages compared to other similar technologies.

The resulting brightness is about 20 times more intense than existing competitors on the market. Another key feature is self-repair. As the bonds between the molecules are reversible, the material repairs itself after cuts or punctures. The process takes place under environmental conditions, without having to heat or chemically treat the damaged area. The technology could be used to build long-lasting and energy efficient wireless displays. HELIOS could also be used to build the skin of soft-bodies robots for use in dark environments such as disaster sites.